7 CNC Axes Industry Steel CNC Metal Cnc 3D H I Beam Drilling Cutter Machine PLC Control

Product Introduction:

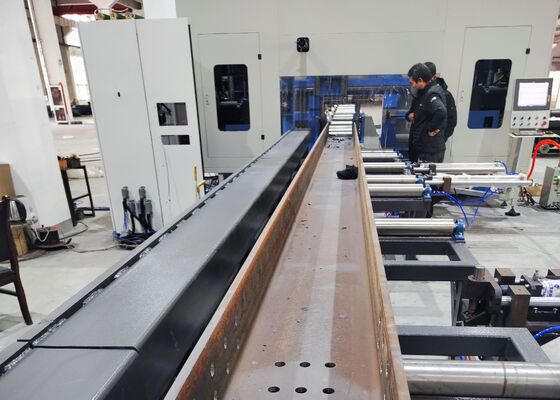

This machining center is specifically engineered for drilling operations on H-beams. Featuring three high-speed precision drilling spindles, it performs drilling processes on workpieces with remarkable efficiency. Offering outstanding machining precision and intuitive operational features, this equipment stands as a vital high-performance solution in the steel structure industry. It is widely applied across critical sectors such as construction engineering, bridge infrastructure, tower mast production, and grid structure projects.

Product configuration information:

| H beam parameter |

Max. Size Width x Height |

1250x600mm |

| Min. Size Width x Height |

200×75mm |

| Max. Beam Length |

12000mm |

| Main spindle |

Qty. |

3 |

| Model |

BT40 |

| Motor power |

3x11 kW |

| Spindle speed |

200~3000 r/min |

| Max. Hole diameter |

φ40 mm |

| Motor power |

Feed servo motor power |

2x3 kW |

| Positioning servo motor power |

2x3 kW |

| Processing Accuracy |

Hole distance deviation |

Two holes within 1 meter |

±0.5 |

| The allowable deviation value increases by ±0.2mm for every additional 1 meter of the hole distance, and the maximum does not exceed ±2mm |

| End margin deviation |

±1.0 mm |

| Hydraulic system |

Hydraulic pump pressure |

7 MPa |

| Oil pump motor power |

7kW |

| Electrical System |

Control method |

PLC |

| Number of CNC axes |

7 |

| Overall size (L x W x H) |

32000x6200x4000 |

Product Features

1. This 3D H-beam drilling and cutting machine is primarily composed of the main machine body, CNC feeding system, material conveyor, electrical system, hydraulic system, cooling system, lubrication system, waste bin, and other related components. Featuring a fixed bed structure and a movable workpiece setup, the machine is ideally suited for processing large-scale H-beams. It supports continuous production operations and is distinguished by its high level of automation.

2. The drilling machine body comprises the bed, CNC sliding table assemblies, support devices, upper pressing units, side pressing units, and detection systems. The CNC sliding table components include the fixed side, movable side, and the upper-unit CNC sliding table. Specifically designed for H-beam drilling operations, the sliding table assemblies consist of a sliding plate, sliding table base, spindle headstock, high-speed mechanical spindle, tool cylinder, variable-frequency motor, servo motor, linear guides, and lead screws.

3. The CNC feeding system is comprised of brackets, gears, racks, servo motors, reducers, and manipulators. The servo motor drives the manipulator to facilitate the H-beam's movement along the X-axis, enabling accurate feeding and precise positioning of the workpiece.

4. The material conveyor consists of both an in-feeding conveyor and an out-feeding conveyor. The in-feeding conveyor includes conveyor brackets, support rollers, and side-pushing devices, all specifically designed to transport profiled steel blanks, achieve Y-axis positioning of the blanks, and work in conjunction with the CNC feeding system to complete the material feeding process. The out-feeding conveyor, made up of material channel brackets and support rollers, is dedicated to transporting finished workpieces.

5. The cooling system utilizes both internal and external cooling methods, employing oil mist to cool the borehole. This approach offers several advantages, including reduced coolant consumption, which promotes cost efficiency, environmental sustainability, and minimized wear on the drill bit.

6. The hydraulic system supplies power to the upper pressing device, side pressing device, tool cylinder, and other associated components.

7. The pneumatic system is designed to provide power to the manipulator, testing cylinder, and similar equipment.

8. The lubrication system employs a combination of centralized and manual lubrication methods. Centralized lubrication is primarily used for the timed and precise lubrication of the main linear guides and lead screws.

9. The machine tool's control system consists of a host computer, PLC, and other related components. **Programming Method:** Processing programs are generated by inputting CAD drawings or processing parameters via a USB interface or keyboard. These programs can be stored, retrieved, displayed, and transmitted at any time based on part numbers. The machine tool not only allows for manual adjustment and control of individual processing parameters but also supports fully automated control for the entire processing sequence.

During sample demonstration sessions, the CNC beam and sheet metal drilling, marking, and shearing machine effectively showcases its processing capabilities when working with standard H-beam samples—featuring varying flange widths and web thicknesses—as well as channel steel samples of different sizes. The specimens presented in these demonstrations clearly highlight the equipment's ability to achieve accurate hole placement, smooth tapped threads, and well-defined marking patterns, thereby fully demonstrating its high precision and reliability in real-world application scenarios.

The High-Speed CNC H-Beam Drilling, Marking, and Shearing Machine is primarily utilized in steel structure manufacturing plants and bridge construction projects. In steel structure workshops, it delivers precise machining for H-beams used in frameworks and support structures, thereby ensuring a strong foundation for the stable assembly of steel structures. In bridge construction, the equipment performs high-precision drilling operations on H-beams, which not only improves the structural integrity of bridges but also enables them to effectively withstand long-term loads. With exceptional operational efficiency, this machine provides reliable support for these critical infrastructure sectors, ensuring the seamless progression of related projects.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!