Macchina automatica per linea angolare CNC per punzonatura e taglio di acciaio angolare nella produzione di torri

Introduzione al prodotto:

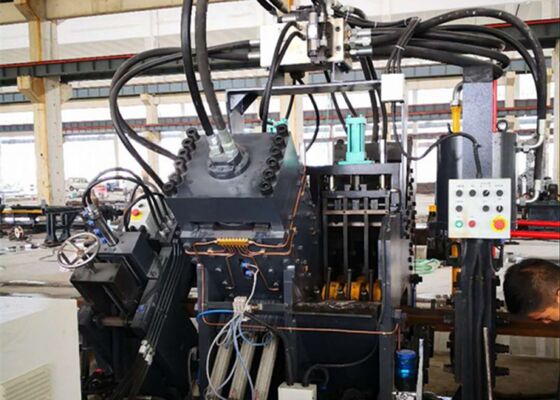

La linea di produzione CNC ad alta velocità per punzonatura, marcatura e taglio di acciaio angolare della serie JNC è costituita principalmente da un'unità di punzonatura, un'unità di marcatura, un'unità di taglio, un trasportatore trasversale, un trasportatore rotante, un trasportatore di alimentazione, un trasportatore di scarico, un carrello di alimentazione CNC, un sistema idraulico, un sistema elettrico e un sistema pneumatico, tra gli altri componenti chiave. Questa linea di produzione è progettata principalmente per la lavorazione automatizzata di acciaio angolare all'interno dell'industria manifatturiera di torri. Il flusso di lavoro di elaborazione è controllato numericamente, vantando una praticità operativa estremamente elevata. Facilita capacità di produzione automatizzate, ad alta precisione, multi-varietà e su larga scala.

Specifiche:

| Modello |

JNC1010 |

JNC1412 |

JNC1616 |

JNC2020 |

| Dimensione angolare (mm) |

40х40х3~

100х100х10 |

40х40х3~

140х140х12 |

40х40х3~

160х160х16 |

50х50х4~

200х200х20 |

| Max. Punzonatura (Dia. х Thi.) (mm) |

Φ26х10 |

Φ26х12 |

Φ26х16 |

Φ26х20 |

| Forza di punzonatura (kN) |

630 |

630/1000 |

1000 |

1000/1200 |

| Forza di marcatura (kN) |

630 |

630/1000 |

1000 |

1000/1200 |

| Forza di taglio (kN) |

1000 |

2000 |

3000 |

2200/4300 |

| Lunghezza massima del grezzo (m) |

12 |

12 |

14 |

14 |

| Lunghezza massima del finito (m) |

8 |

8 |

12 |

12 |

| Punzoni per lato |

2 |

2 o 3 |

3 |

3 |

| Gruppo di lettere di marcatura |

4 |

4 |

4 |

4 |

| Numero di lettere per gruppo |

12 |

12/18 |

18 |

18 |

| Dimensione carattere (mm) |

14x10x19 |

| Assi CNC |

3 |

| Modalità di taglio |

Lama singola |

Lama doppia o Lama singola |

| Metodo di raffreddamento |

Raffreddamento ad acqua/Raffreddamento ad aria/Refrigeratore d'olio |

| Velocità di alimentazione angolare (m/min) |

80 |

80 |

80 |

60 |

| Modalità di programmazione |

Software di tracciatura o programmazione delle istruzioni |

| Dimensione complessiva (m) |

Circa 25x6.5x2.5 |

Circa 25x6.5x2.5 |

Circa 32x7x3 |

Circa 32x7x3 |

I parametri sopra indicati possono essere regolati e modificati in base alle specifiche esigenze del cliente.

Caratteristiche del prodotto:

1. L'unità di punzonatura è dotata di due o tre set, che possono essere configurati con tre tipi di punzoni di diametri diversi. I tre set di matrici di punzonatura sono posizionati tramite controllo numerico per regolare la spaziatura. È in grado di punzonare sia fori rotondi che fori ovali. Le sue elevate velocità di alimentazione e punzonatura ottimizzano l'efficienza produttiva; per acciaio angolare di specifiche 50×50×4 mm, l'uscita raggiunge le 9–10 tonnellate per turno di otto ore.

2. L'unità di marcatura adotta un design strutturale chiuso con rigidità superiore. È fornita di quattro set di cassette di caratteri, che vengono selezionate tramite controllo del programma, e la spaziatura di marcatura può essere impostata arbitrariamente. Inoltre, viene offerta una configurazione opzionale di tipo a disco. Il sistema di marcatura a disco comprende 10 file di caratteri e consente la selezione automatica dei caratteri senza la necessità di intervento manuale, migliorando così sostanzialmente l'efficienza di marcatura.

3. L'unità di taglio adotta un meccanismo di taglio a lama singola, un design strutturale rinomato per la sua robusta forza di taglio. Ogni ciclo di taglio non produce materiale di scarto, mentre la superficie di taglio mantiene un'eccezionale pulizia e levigatezza. L'alloggiamento della lama è dotato di una configurazione a porta aperta, che consente procedure di sostituzione della lama rapide e sicure.

4. Il tavolo portamateriali orizzontale trasporta l'acciaio angolare al rack portamateriali rotante. Azionato da un motore e da un gruppo riduttore, il rack portamateriali rotante facilita il posizionamento stabile dell'acciaio angolare sul trasportatore di alimentazione.

5. Il pezzo viene bloccato e alimentato dal carrello di alimentazione CNC, che offre una precisione di posizionamento superiore. Il carrello di alimentazione CNC è azionato da un servomotore, integrato con feedback dell'encoder fotoelettrico e funzionalità di controllo a circuito chiuso.

Questi provini, derivati dalla linea di produzione di punzonatura, taglio e marcatura di acciaio angolare, comprendono le specifiche standard e gli scenari di lavorazione ampiamente adottati nell'industria manifatturiera di torri in acciaio angolare. Consentono agli utenti di valutare direttamente la qualità di lavorazione, le prestazioni di precisione e gli standard di lavorazione dell'apparecchiatura.

Nella costruzione di linee di trasmissione ad altissima tensione (UHV) - dove le torri di trasmissione devono resistere a condizioni meteorologiche estreme e carichi pesanti - questa apparecchiatura svolge un ruolo fondamentale nella lavorazione dei componenti in acciaio angolare che formano la struttura primaria delle torri. Conduce in modo affidabile operazioni di foratura e stampaggio sull'acciaio angolare utilizzato per i corpi delle torri, i bracci trasversali e altri componenti strutturali chiave. Ciò garantisce un'accurata precisione dimensionale e robuste prestazioni di connessione, mantenendo così la stabilità strutturale complessiva delle torri di trasmissione.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!