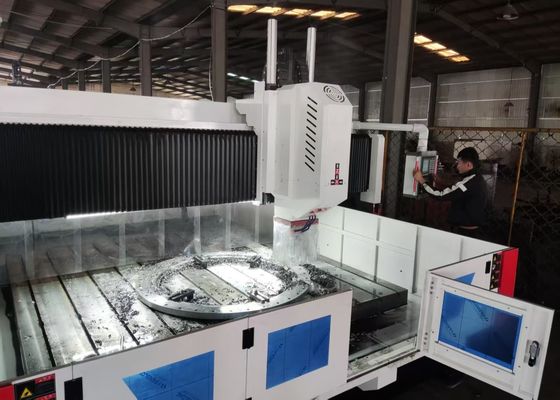

2pcs Drilling Power Head Double Spindle CNC Drilling Milling Machine 30~6000r/min Spindle Speed

Application:

This CNC gantry-type sheet metal drilling and milling machine is specifically engineered to conduct drilling, chamfering, tapping, milling, and boring operations on plate workpieces and structural components. It delivers high-efficiency hole-machining capabilities for workpieces such as flanges, discs, rings, and plates within its specified thickness range. The equipment is capable of processing through holes and blind holes, and is compatible with both single-material and composite-material components. Equipped with advanced numerical control technology, this machine tool offers superior operational convenience and enables automated, high-precision production of a wide range of products in large-scale manufacturing environments.

Specifications:

| Workpiece size |

LxW |

13000x1000 mm |

| Gantry height |

600 mm (It can also be determined according to the foundation)

|

| Workbench |

T-slot width |

28mm |

| Drilling power head |

Qty. |

2 |

| Spindle taper |

BT40-150 |

|

Max.drilling diamter

(Ordinary carbon steel)

|

Φ30 mm |

| Tapping diameter |

M3-M10 |

| Spindle speed |

30~6000 r/min |

| Servo spindle motor power |

7.5kW |

| Distance from the lower end of the spindle to the worktable |

200-600mm |

|

Lateral movement of power head (X axis)

|

Max.horizontal stroke |

1000 mm |

| Lateral movement speed |

0~8 r/min |

| Servo motor power for lateral movement |

2.4kW |

|

Gantry longitudinal movement (Y axis)

|

Max. feed stroke |

13000 mm |

| Feed moving speed |

0~8 m/min |

| Feed servo motor power |

2x2.4kW |

| Vertical ram feed motion (Z axis) |

Max. stroke |

300 mm |

| Moving speed |

0~5 m/min |

| Servo motor power |

7.5kW (Brake) |

| Three-axis positioning accuracy |

X/Y/Z/A/B/C |

±0.015/1000mm |

| Three-axis repeat positioning accuracy |

X/Y/Z/A/B/C |

±0.01/1000mm |

| Overall size |

LxWxH |

13000x3000x2500 mm |

Product Features

1. Transmission System:

Adopts Taiwan-sourced guide rails and a high-precision slider configuration, ensuring smooth operational performance and enhanced heavy-load bearing capacity.

1). The X-axis incorporates two rolling linear guide rails serving as lateral guiding and load-bearing rails, fulfilling high-speed drilling operational demands. For X-axis transmission, an AC servo motor is utilized to drive a precision ball screw, enabling accurate linear motion.

2). The Y-axis is outfitted with two heavy-duty rolling linear guide rails on each side, with three square rail sliders mounted on each guide rail—collectively constituting the Y-axis sliding mechanism. This structural design satisfies the high rigidity and strength requirements of the gantry frame, while delivering technical merits including a low friction coefficient, high movement velocity, superior vibration damping performance, and extended service life. For X-axis drive, dual servo motor synchronous drive technology is adopted: one servo motor is configured on each side to synchronously drive the ball screw for rotation, thereby actuating the gantry frame and realizing CNC machining operations.

3). The spindle housing is equipped with four heavy-duty linear guide rails, providing exceptional motion rigidity, high positioning precision, and outstanding low-speed stability.

3. Automatic Lubrication System and Protective Mechanisms:

This machine tool is furnished with a Taiwan-manufactured volumetric pressure-distributing automatic lubrication system. It delivers automatic lubrication to all moving components—including guide rails, lead screws, and gear racks—without any coverage gaps, effectively safeguarding the machine tool’s service life. The X-axis and Y-axis of the equipment are outfitted with dust-proof protective covers, while water-resistant splash shields are installed around the worktable.

4. Comprehensive Siemens/KND CNC Control System:

The motor is driven by high-precision absolute-value series servo motors. It is equipped with an RS232 interface and a color display screen featuring a Chinese-language operating interface, while also supporting on-site and external USB input functionality.

This high-performance CNC gantry plate sheet metal drilling and marking industrial equipment is elaborately engineered for the precision machining of plate-type components and structural parts. Tailored specifically for processing workpieces including flanges, discs, rings, and flat plates, it features a core requirement that the thickness of such workpieces must strictly conform to the machine’s specified effective machining parameters.

In steel structure workshops, this equipment delivers precision drilling and milling operations for structural plates and connecting components, thereby establishing a robust foundation for the stable assembly of steel frameworks. Within the wind energy sector, it provides high-precision machining solutions for wind turbine towers and flanges—an indispensable process that ensures these components are capable of withstanding harsh environmental conditions (e.g., strong winds, temperature fluctuations). For bridge construction projects, the equipment processes bridge girders and support brackets, enabling the formation of stable, durable connections engineered to bear dynamic loads throughout the bridge’s prolonged service life.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!